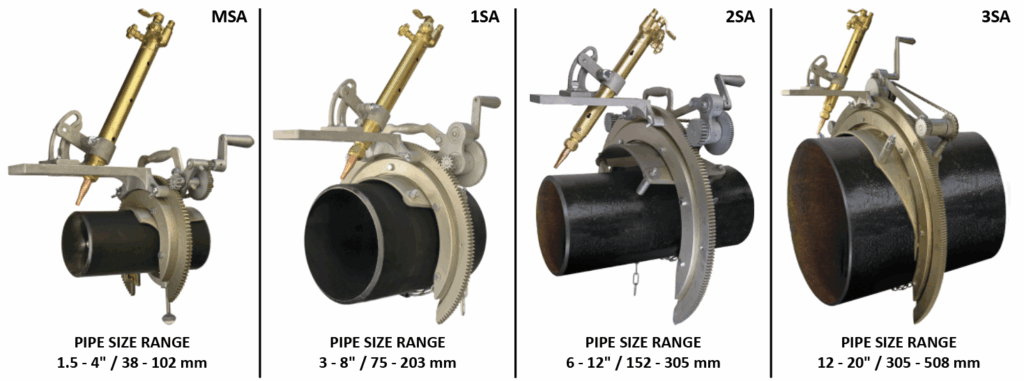

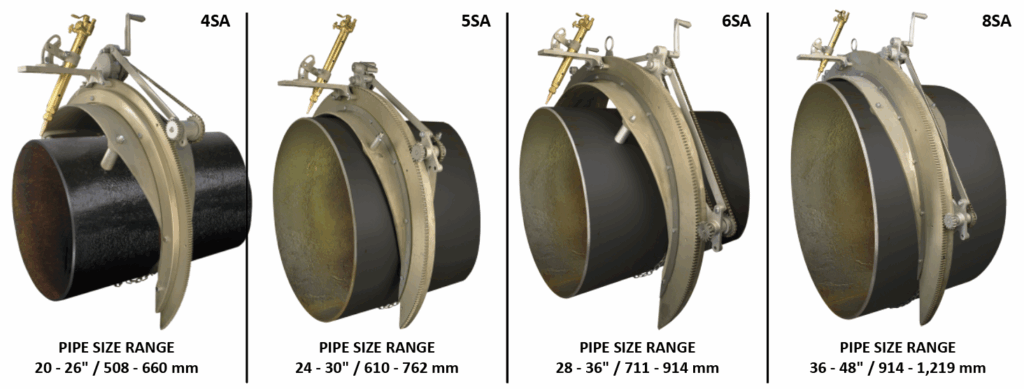

The industry standard for over 90 years, the Mathey Dearman saddle machine is versatile, simple to use, and perfect for almost any pipe cutting and beveling application. Lightweight and durable, the Mathey Dearman machine is designed for accurate, quality cuts on 1.5 – 48″ / 38 – 1,219 mm pipes.

Saddle Machine Motorized / Manual

ONLY STOCKED IN THE AMERICAS

Mobile Nav

Manual saddle machine includes:

- Saddle machine

- Torch arm

- Torch carrier assembly (torch diameter 1.375″ / 35 mm)

- Boomer assembly (fastens the machine to the pipe)

- Spacer bolt set

- Parts and operating manual

Note: Machine torches sold separately.

Want the easiest way to get a perfect cut every time?

Motorized saddle machines from Mathey Dearman are precise and fast, delivering smooth cuts requiring little or even no grinding.

Both experienced and inexperienced welders can benefit from the increased productivity (up to 5 times quicker!) and cut quality of motorized saddle machines compared to traditional hand-cutting or manual machines.

Motorized PLASMASPEED saddle machines can use 110/230 VAC for pipe sizes 1.5 – 48″ / 38 – 1,219 mm and can operate at increased cutting speeds to use powerful plasma torches.

It’s what Mathey Dearman calls PLASMASPEED!

Motorized saddle machine includes:

- 110/230 VAC motorized saddle machine

- Torch arm

- Torch carrier assembly

- Boomer assembly (fastens the machine to the pipe)

- Spacer bolt set

- Parts and operating manual

- Mounting bracket

- Right-angle precision stepper motor

- Motor control box

- Plasma communication cable (10 foot length, compatible with Hypertherm plasma cutter with a CPC port)

Note: Machine torches sold separately – machine shown with optional step spacers and pro model torch.

Conventional cutting vs. saddle cutting time

Hand cutting. Time: 30 minutes

- 8″ schedule 40 pipe being cut by hand. Time includes measuring, cutting and grinding

- Longer than necessary layout time

- Excessive amount of time to cut the pipe

- Inaccurate/uneven cut requiring grinding

- Extended fit-up time

- Uneven weld gap

Mathey Dearman cutting. Time: 6 minutes

- 8″ schedule 40 Pipe being cut with a 1SA manual saddle machine

- Perfect cut

- No grinding

- Perfect fit-up

Manual Saddle Machines

Manual Saddle Machines

| MACHINE MODEL | MSA | 1SA | 2SA | 3SA |

| Manual with spacer bolts | 03.0100.000 | 03.0101.000 | 03.0102.000 | 03.0103.000 |

| Manual with step spacers | n/a | 03.01S1.000 | 03.01S2.000 | 03.01S3.000 |

Motorized Saddle Machines / PLASMASPEED

| MACHINE MODEL | MSA | 1SA | 2SA | 3SA |

| Motorized with spacer bolts 115/230 VAC | 03.0100.S01 | 03.0101.S01 | 03.0102.S01 | 03.0103.S01 |

| Motorized with step spacers 115/230 VAC | n/a | 03.01S1.S01 | 03.01S2.S01 | 03.01S3.S01 |

PLASMASPEED Retrofit Kits

| MACHINE MODEL | MSA | 1SA | 2SA | 3SA |

| PLASMASPEED retrofit kits 115/230 VAC | 03.0100.SA1 | 03.0101.SA1 | 03.0101.SA1 | 03.0103.SA1 |

General Specifications

| MACHINE MODEL | MSA | 1SA | 2SA | 3SA |

| Pipe size | 1.5 – 4″ / 38 – 102 mm | 3 – 8″ / 75 – 203 mm | 6 – 12″ / 152 – 305 mm | 12 – 20″ / 305 – 508 mm |

| Net weight | 10 lbs / 5.00 kg | 16 lbs / 7.00 kg | 26 lbs / 12.00 kg | 50 lbs / 22.00 kg |

| Estimated shipping weight | 12 lbs / 5.44 kg | 24 lbs / 10.89 kg | 34 lbs / 15.40 kg | 73 lbs / 33.10 kg |

| Shipping dimensions | 12 x 12 x 10″ / 305 x 305 x 254 mm | 18 x 18 x 11.5″ / 457 x 457 x 492 mm | 23 x 23 x 12.5″ / 584 x 584 x 318 mm | 34 x 32 x 12″ / 864 x 813 x 305 mm |

| Maximum speed (motorized) ipm* / mpm** | 141 / 3,581 | 71 / 1,803 | 89 / 2,261 | 34 x 32 x 12″ / 864 x 813 x 305 mm |

| Minimum speed (motorized) ipm* / mpm** | 4 / 102 | 4 / 102 | 6 / 152 | |

| Includes spacer bolts to cut pipe sizes | 2″, 3″, 4″ / 60.3, 88.9, 114.3 mm | 3″, 4″, 6″, 8″ / 88.9, 114.3, 168.2, 219 mm | 6″, 8″, 10″, 12″ / 168.2, 219, 273, 323.8 mm | 12″, 14″, 16″, 18″, 20″ / 323.8, 356, 406, 457, 508 mm |

* inches per minute | ** millimeters per minute

Machine Saddle Machines

Manual Saddle Machines

| MACHINE MODEL | 4SA | 5SA | 6SA | 8SA |

| Manual with spacer bolts | 03.0104.000 | 03.0105.000 | 03.0106.000 | 03.0108.000 |

| Manual with step spacers | n/a | n/a | n/a | n/a |

Motorized Saddle Machines / PLASMASPEED

| MACHINE MODEL | 4SA | 5SA | 6SA | 8SA |

| Motorized with spacer bolts 115/230 VAC | 03.0104.S01 | 03.0105.S01 | 03.0106.S01 | 03.0108.S01 |

| Motorized with step spacers 115/230 VAC | n/a | n/a | n/a | n/a |

PLASMASPEED Retrofit Kits

| MACHINE MODEL | 4SA | 5SA | 6SA | 8SA |

| PLASMASPEED retrofit kits 115/230 VAC | 03.0103.SA1 | 03.0105.SA1 | 03.0105.SA1 | 03.0105.SA1 |

General Specifications

| MACHINE MODEL | 4SA | 5SA | 6SA | 8SA |

| Pipe size | 24 – 30″ / 610 – 762 mm | 28 – 36″ / 711 – 914 mm | 36 – 48″ / 914 – 1,219 mm | |

| Net weight | 20 – 26″ / 508 – 660 mm | 110 lbs / 50.00 kg | 180 lbs / 82.00 kg | 287 lbs / 130.00 kg |

| Estimated shipping weight | 75 lbs / 34.00 kg | 185 lbs / 71.70 kg | 295 lbs / 133.80 kg | 537 lbs / 243.60 kg |

| Shipping dimensions | 150 lbs / 68.00 kg | 40.5 x 41 x 19″ / 1,029 x 1,041 x 423 mm | 57 x 43 x 18″ / 1,488 x 1,002 x 483 mm | 69 x 60 x 21″ / 1,753 x 1,524 x 533 mm |

| Maximum speed (motorized) ipm* / mpm** | 40.5 x 41 x 19″ / 1,029 x 1,041 x 423 mm | 34 / 864 | 35 / 889 | 36 / 914 |

| Minimum speed (motorized) ipm* / mpm** | 53 / 1,346 | 8 / 203 | 5 / 127 | 5 / 127 |

| Includes spacer bolts to cut pipe sizes | 7 / 178 | 24″, 26″, 28″, 30″ / 610, 660, 711,762 mm | 28″, 30″, 36″ / 711, 762, 914 mm | 36″, 38″, 40″, 42″, 48″ / 914, 964, 1,016, 1,067, 1,219 mm |

* inches per minute | ** millimeters per minute

Double Torch Arm

Reduce setup and cutting time by up to 50% with the double torch arm accessory. By eliminating the need to rotate one torch to obtain a forward or back bevel on the pipe end, the double torch arm dramatically reduces cutting and beveling time. Torch arm accommodates American torch rack size only.

| PART NO. | MODEL | PIPE SIZE | PACKAGED WEIGHT | |

| 03.0101.030 | 1SA | 3 – 8″ / 88.9 – 219 mm | 5 lbs / 2.30 kg | 20 x 6 x 6″ / 508 x 152 x 152 mm |

| 03.0102.015 | 2SA | 8 – 12″ / 219 – 323.8 mm | 5 lbs / 2.30 kg | 20 x 6 x 6″ / 508 x 152 x 152 mm |

| 03.0103.030 | 3SA | 12 – 20″ / 323.8 – 508 mm | 5 lbs / 2.30 kg | 23 x 10 x 9″ / 584 x 254 x 229 mm |

| 03.0104.021 | 4SA | 20 – 26″ / 508 – 660 mm | 5 lbs / 2.30 kg | 23 x 10 x 9″ / 584 x 254 x 229 mm |

| 03.0105.025 | 5SA | 24 – 30″ / 610 – 762 mm | 5 lbs / 2.30 kg | 23 x 10 x 9″ / 584 x 254 x 229 mm |

| 03.0106.018 | 6SA | 28 – 36″ / 711 – 914 mm | 5.5 lbs / 2.50 kg | 23 x 10 x 9″ / 584 x 254 x 229 mm |

| 03.0108.014 | 8SA | 36 – 48″ / 914 – 1,219 mm | 5.5 lbs / 2.50 kg | 23 x 10 x 9″ / 584 x 254 x 229 mm |

Pro Model Torch Arm

Choose the pro model torch arm with the innovative out-of-round roller attachment to create perfect cuts and bevels on oversize, undersize or out-of-round pipe. Torch arm accomodates American torch rack size only.

| PART NO. | DESCRIPTION | PACKAGED WEIGHT | PACKAGED DIMENSIONS | |

| 03.0209.000 | Pro model with out of round | 9.50 lbs / 4.30 kg | 16 x 8 x 8″ | 406 x 203 x 203 mm |

| 03.0209.001 | Pro model basic assembly | 7 lbs / 3.20 kg | 16 x 8 x 8″ | 406 x 203 x 203 mm |

| 03.0209.012 | Tracer point | 1.60 lbs / 0.70 kg | 12 x 6 x 6″ | 305 x 152 x 152 mm |

Torch holders that can accommodate up to 2″ barrel diameter torches are available

Out-Of-Round Roller Attachment

The out-of-round roller attachment kit, which can be fitted on the pro model torch arm, compensates for oversize and undersize pipe, handling out-of-round conditions up to 1/4″ / 6 mm. This separate attachment comes with all required parts and assembly instructions.

| PART NO. | DESCRIPTION | PACKAGED WEIGHT | PACKAGED DIMENSIONS |

| 03.0209.003 | Out-of-round roller attachment kit | 2.50 lbs / 1.10 kg | 12 x 6 x 6″ / 305 x 152 x 152 mm |

Cam-Adjustable Torch Carrier

The cam-adjustable torch carrier (diameter of 1.375″ / 35 mm) makes it simple to make perfect, no-notch cuts every time. Just start the cut away from the desired cut line, use the knurled cam adjustment knob to move the torch into the cut line, then start cutting.

In addition, the torch holder’s large wing screw makes tightening the torch in the torch holder easy, even when wearing gloves. The innovative design even allows forward or back-beveling without the need to reverse the torch holder in the torch arm. PART NO. 03.0100.052

Saddle machine storage box

Store and help protect the saddle machine, torch, torch arm, torch carrier, spacer bolts, parts, and operating manual in this specially-designed storage box.

MSA, 1SA, and 2SA storage boxes are made of 16-gauge, powder-coated steel, with attached lifting handles.

Storage boxes for saddle machines larger than the 3SA are made of plywood with reinforced corners and edges.

| PART NO. | MODEL | DIMENSIONS | MANUAL OR MOTORIZED | BOX TYPE | PACKAGED WEIGHT |

| 03.0100.BOX | MSA | 18 x 18 x 10″ / 457 x 457 x 254 mm | Manual only | Metal | 23 lbs / 10.40 kg |

| 03.0101.BOX | 1SA | 23 x 23 x 13″ / 584 x 584 x 330 mm | Manual only | Metal | 33 lbs / 14.90 kg |

| 03.0102.BOX | 2SA | 34 x 32 x 12″ / 635 x 559 x 305 mm | Manual only | Metal | 41 lbs / 18.50 kg |

| 03.0103.BOX | 3SA | 34 x 32 x 14″ / 635 x 559 x 356 mm | Manual or motorized | Wood | 60 lbs / 27.00 kg |

| 03.0104.BOX | 4SA | 40 x 38 x 14″ / 1,016 x 965 x 356 mm | Manual or motorized | Wood | 79 lbs / 35.60 kg |

| 03.0105.BOX | 5SA | 42 x 40 x 14″ / 1,067 x 1,016 x 356 mm | Manual or motorized | Wood | 84 lbs / 37.80 kg |

| 03.0106.BOX | 6SA | 56 x 48 x 16″ / 1,422 x 1,219 x 406 mm | Manual only | Wood | 100 lbs / 45.00 kg |

| 03.0108.BOX | 8SA | 70 x 56 x 19″ / 1,778 x 1,422 x 483 mm | Manual only | Wood | 125 lbs / 56.30 kg |

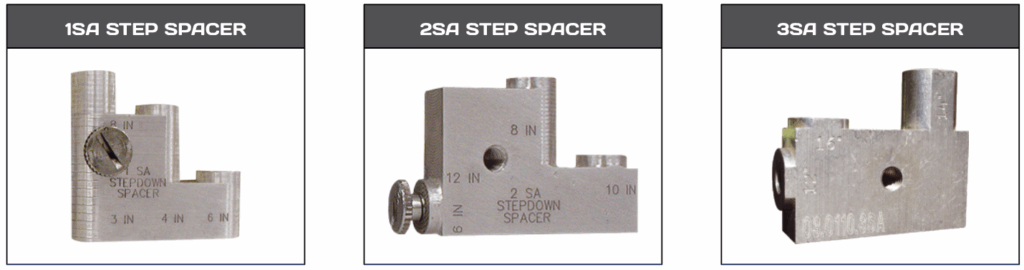

Self-Storing Step-Down Spacer

Combining multiple spacer bolt sizes into one easy-to-use part, the step-down spacers are machined to the same tolerances as spacer bolts. Each step spacer covers a range of four (4) pipe sizes, eliminating the need to store 16 spacer bolts. No more searching for lost or misplaced spacer bolts with high-quality aluminum alloy or stainless steel self-storing step-down spacers.

Step Spacer Kit

| PART NO. | DESCRIPTION | FOR PIPE SIZES | PACKAGED WEIGHT |

| 03.0110.1SAKIT | 1SA Step Spacers | 3″, 4″, 6″, 8″ / 88.9 mm, 114.3 mm, 168.2 mm, 219 mm | 1.60 lbs / 0.70 kg |

| 03.0110.2SAKIT | 2SA Step Spacers | 6″, 8″, 10″, 12″ / 168.2 mm, 219 mm, 273 mm, 323.8 mm | 1.60 lbs / 0.70 kg |

| 03.0110.3SAKIT | 3SA Step Spacers | 12″, 14″, 16″, 18″, 20″ / 323.8 mm, 356 mm, 406 mm, 457 mm, 508 mm | 1.60 lbs / 0.70 kg |

Saddle Machine Spacer Bolts

Spacer Bolt Kits include the spacer bolts in one handy container available for any Mathey Dearman saddle machine model. An actual-size diagram is located on the lid, making finding the correct Spacer Bolts quick and easy. All spacer bolts are precision-machined for maximum cutting accuracy and labeled with the Mathey Dearman logo and Part No. for quick identification. Actual size is shown on the box lid for quick spacer bolt identification.

| PART NO. | DESCRIPTION | FOR PIPE SIZES | PACKAGED WEIGHT |

| 03.0MSA.KIT | MSA | 2″, 3″ / 60.3 mm, 88.9 mm | 1 lbs / 0.50 kg |

| 03.01SA.KIT | 1SA | 3″, 4″, 6″, 8″ / 88.9 mm, 114.3 mm, 168.2 mm, 219 mm | 4 lbs / 1.80 kg |

| 03.02SA.KIT | 2SA | 6″, 8″, 10″, 12″ / 168.2 mm, 219 mm, 273 mm, 323.8 mm | 5 lbs / 2.30 kg |

| 03.03SA.KIT | 3SA | 12″, 14″, 16″, 18″, 20″ / 323.8 mm, 356 mm, 406 mm, 457 mm, 508 mm | 9 lbs / 4.10 kg |

| 03.04SA.KIT | 4SA | 20″, 22″, 24″, 26″ / 508 mm, 559 mm, 610 mm, 660 mm | 10 lbs / 4.50 kg |

| 03.05SA.KIT | 5SA | 24″, 26″, 28″, 30″ / 610 mm, 660 mm, 711 mm, 762 mm | 10 lbs / 4.50 kg |

| 03.06SA.KIT | 6SA | 28″, 30″, 36″ / 711 mm, 762 mm, 914 mm | 20 lbs / 9.00 kg |

| 03.08SA.KIT | 8SA | 36″, 38″, 40″, 42″, 48″ / 916 mm, 964 mm, 1,016 mm, 1,069 mm, 1,219 mm | 20 lbs / 9.00 kg |

* No spacers required for 4″ pipe set up

OPERATING MANUAL

Related Products